Eco-Design for Furniture: Cut Costs & Emissions Through Sustainable Design

- Victoria Burt

- Apr 28, 2025

- 5 min read

Why Eco-Design Is a Competitive Advantage in Furniture Manufacturing

Eco-design has long carried the whiff of compromise. To some, it evokes images of overpriced bamboo, consultants with hemp tote bags, and regulations cooked up in Brussels by people who’ve never shipped a sofa.

Historically, it was seen as the cost of appeasing environmental lobbies or winning awards no one remembered.

But here’s the truth: furniture executives are now waking up to the fact that eco-design is no longer a moral obligation. It's a margin opportunity.

“Thanks to progress in material science, energy storage, predictive modelling, and generative AI, we’ve reached a moment where designing for sustainability can actually reduce costs, not just emissions.”

This isn’t about idealism. It’s about measurable business outcomes.

A designer working with 3D modeling software should be able to simulate material performance, assess carbon footprint, and make smarter substitutions—all before a single part is sourced.

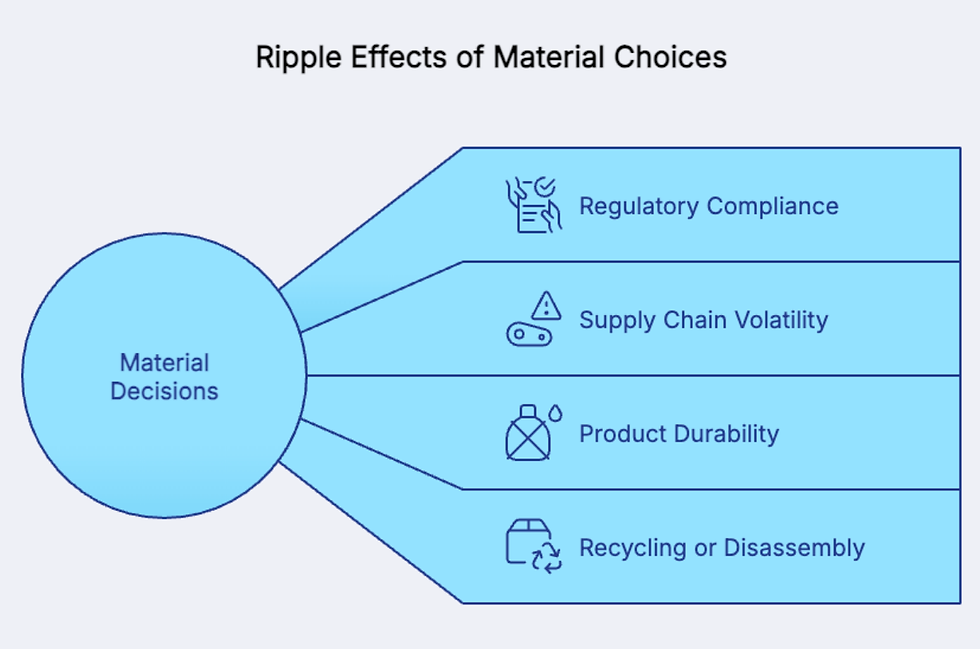

These decisions ripple downstream, improving everything from freight efficiency to recyclability and compliance readiness.

“Eco-design today isn’t about marketing optics. It’s about engineering your margins from the inside out.”

And yet, many industrial design teams still treat this as a future-state ambition—something to tackle after manufacturing, or at the time of CSR report filing.

But what if that future is already here?

Where Profits Leak: Hidden Costs in Furniture Design and Manufacturing

In furniture manufacturing, behind the spreadsheets lie the silent culprits: design revisions that come too late, product specs that err on the side of excess, supply chain whiplash, and returns that eat your revenue on the way out.

Let’s start with late stage redesigns—the quiet saboteur of timelines and margins. A last-minute material swap sounds innocuous until it triggers a domino effect: revised engineering specs, scrapped parts, rushed reassembly, and extended labor hours. In essence, you’re paying to build the same thing twice.

But one of the more insidious causes of rework today isn’t just reactive decision-making—it’s disconnected design workflows. Most CAD tools weren’t built for sustainability or compliance. They don’t flag whether a material violates upcoming regulations or pushes your carbon footprint over the limit. So designers soldier on, unaware they’re embedding risk into the blueprint. By the time someone downstream raises the red flag—six months in—it’s back to the drawing board. Multiply that across SKUs and teams, and the cost curve bends sharply upward.

According to manufacturing platform Beamup, rework can inflate the total cost of a project by 20% to 50% [^1]. And unlike raw material prices or freight surcharges, these losses rarely get flagged in time. The lesson is simple but costly to ignore: every late design change carries a price, and catching issues early (especially the invisible ones) is how you prevent a cascade of downstream expenses.

Then there’s the hidden cost of good intentions taken a bit too far. Over-engineering may sound like a high-class problem, until you start running the numbers. Extra bracing, excessive load specs, or redundant joinery might make a table indestructible, but they also make it heavier, pricier to produce, and more costly to ship. In many cases, it’s money left on the table—or rather, built into the table unnecessarily. Studies suggest that trimming design complexity can reduce product costs by 10% to 30%, without compromising quality or function[^2].

And while we’re trimming excess, let’s talk supply chains. Lumber prices spiked over 300% between 2020 and 2021, and container shipping costs soared from $2,000 to over $10,000 per unit[^3][^4]. For a category built on heavy goods and long lead times, those swings weren’t just inconvenient—they were existential. A missed hedging window or a delayed component can still derail an entire quarter.

One can’t ignore the quiet bleed of returns when talking about hidden costs. As more sales shift online, product quality issues now carry real operational costs. A wobbly leg or a fabric mismatch can trigger a return that costs 59% of the original sale value[^5]. Add refurbishing, discounts, and reputational damage, and you’re not just losing a customer, you’re burning margin.

Individually, these might look like isolated hiccups. But more often than not, they trace back to the same root: decisions made too late in the design phase.

The Root Cause: Material Choices Made Without Business Context

Designers aren’t making bad decisions, they’re making incomplete ones.

Materials are often chosen based on:

What was used before

What suppliers offer

What hits the per-unit cost target

And on paper, that can look like good business. The quote checks out. What could go wrong?

Plenty.

Without visibility into the full lifecycle of a material, its carbon footprint, regulatory exposure, supply chain resilience, or what it costs to disassemble and dispose of—you’re effectively building risk into the product from day one.

Take compliance. One UK furniture retailer was fined for importing teak without proper due diligence under EU timber laws, a relatively minor infraction that, under new EU deforestation regulations (EUDR), would now result in products being pulled from shelves and fines of up to 4% of annual EU turnover.

By 2026, furniture manufacturers will be required to prove recyclability, repairability, and environmental impact—documented through Digital Product Passports [^6].

Miss those specs late in the process, and you're looking at a full product redesign—or worse, a product you can’t sell.

Material choices made without these factors in mind can force late-stage pivots that cost time and margin. And the risks don’t stop at compliance.

Few teams account for end-of-life costs like disassembly, landfill fees, or the lost value of non-recyclable parts. A composite that saves money upfront might render an entire product unrecyclable. A misstep in fasteners or adhesives can make disassembly almost impossible. As landfill fees and circularity mandates rise, products that aren’t designed to come apart will cost more to retire than to make[^7].

Add to that the overlooked cost of premature obsolescence. A poor material decision shortens product lifespan, fuels replacement cycles, and balloons long-term costs[^8]. IKEA discovered that extending product life by two years reduced returns and warranty claims while increasing loyalty[^9].

All of this traces back to the same blind spot: material choices made without business context.

Herman Miller (now MillerKnoll) integrated a "Design for Environment" protocol into its process, screening every new material for compliance, recyclability, and long-term cost. In one case, swapping out a mixed-material part for a recyclable alternative didn’t just simplify disassembly—it reduced production cost[^10].

When you bring durability, compliance, and end-of-life considerations into the design phase, you don’t just build greener products. You build smarter margins.

How CarbonSync Builds Sustainability into the Design Workflow

Most sustainability tools are retroactive, they flag issues after it’s too late.

CarbonSync does the opposite.

Embedded in your existing CAD workflows

Delivers AI-powered material recommendations based on your constraints

Flags compliance risks early—before you design in a liability

Quantifies ROI from day one: lower sourcing risk, fewer reworks, faster time to market

“We don’t just show your team the carbon impact—we help them avoid costly mistakes before they happen.”

For furniture companies navigating rising costs, tighter timelines, and stricter regulations, CarbonSync turns material selection into a strategic advantage—not a liability waiting to surface.

What to Do Next: Smarter Design Starts with One Product

If your materials could talk, they’d probably ask why no one looped them into the business strategy.

Ready to see what smarter material choices look like in action?

Good design is deliberate. So are good decisions.